Soft soldering

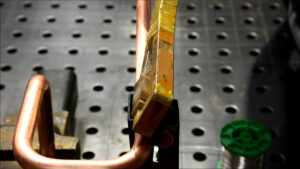

Welcome to the world of precision soldering with VauQuadrat’s innovative deep induction technology. Discover how our advanced technology makes soft soldering an efficient and reliable process, whether you are tinning car body parts or soldering copper pipe fittings.

Find out how VauQuadrat’s advanced deep induction technology is setting new standards in the field of soft soldering.

Fast and risk-free tinning:

Experience a revolutionary method for tinning materials in the bodywork and special vehicle construction sector. Using deep induction technology, you can effortlessly apply soft solder paste, hover the standard inductor at a precisely defined distance above the paste and watch the surface shine with a glossy finish when the power is activated. This innovative technique even allows you to tin uneven surfaces, giving you the flexibility and effectiveness to create soft solder joints.

Advantages when tinning materials:

Discover the benefits of deep induction technology, which ensures precise temperature control and almost never exceeds the melting temperature of the solder in the base material. Our process-reliable tinning takes place without the use of complex temperature measurements; instead, all you need to do is keep an eye on the changing tin paste. This allows you to achieve precise and reliable soft soldering results – efficiently and without complicated measuring procedures or even temperature controls.

Advantages of our technology:

- Speed and safety: With our deep induction technology, you can produce clean and reliable solder joints in the shortest possible time.

- Optimized heat transfer: Take advantage of forming gas and high-silver filler wires to reduce the amount of solder and optimize heat transfer.

- Uniform heating: Our technology ensures uniform heating, resulting in perfect solder joints without the need for time-consuming reworking.

- Practical application examples: Find out how our technology is used in various applications, from car bodies to copper pipes